Manufacturing AI must prove its value. Predictive maintenance promises reduced downtime—but implementation requires careful OT/IT integration. Quality control automation must meet exacting standards. Supply chain optimization demands accurate data and robust systems.

We help manufacturing leaders deploy AI with clear ROI. Our approach focuses on practical implementation, measurable outcomes, and shop floor adoption. From pilot projects to enterprise-wide transformation, we've helped manufacturers across Southeast Asia capture the value of Industry 4.0.

Assembly optimization, quality inspection, and production scheduling for discrete manufacturers.

Process optimization, predictive maintenance, and yield improvement for continuous operations.

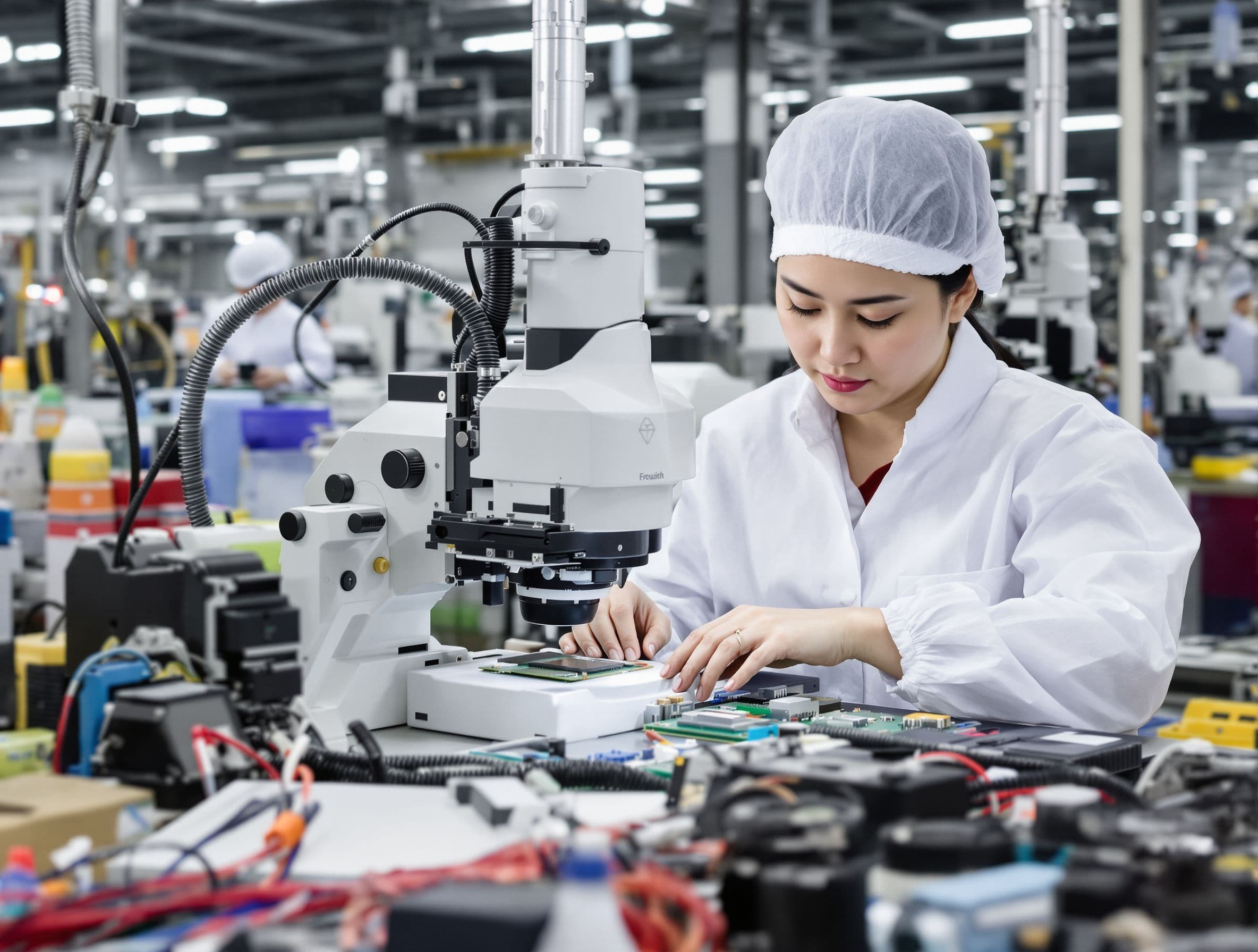

Defect detection, yield optimization, and supply chain resilience for electronics manufacturers.

Quality control, demand forecasting, and regulatory compliance for F&B manufacturers.

We help manufacturing leaders deploy AI with clear ROI. Our approach focuses on practical implementation that proves value within production cycles, then scales systematically across operations.

Prepare floor supervisors and operators to work with AI-assisted quality control and predictive maintenance systems.

Map production workflows to identify high-impact automation opportunities with measurable returns.

Build custom AI solutions for quality inspection, demand forecasting, and supply chain optimization.

Strategic guidance on OT/IT integration, vendor selection, and phased implementation planning.

Maximize training subsidies and government grants available for AI transformation in manufacturing.

Corporate training in Malaysia is increasingly focused on AI and digital transformation. With HRDF claimable programmes, companies can upskill their entire team in AI at zero net cost. This guide covers the best corporate AI training options, HRDF claim process, and how to choose the right programme for your business.

The HRDF levy is a mandatory contribution that funds employee training in Malaysia. Understanding how the levy works, how much your company contributes, exemption rules, and how to maximise your levy utilisation is essential for HR leaders and finance teams. This guide covers everything about HRDF contributions.

Singapore SMEs qualify for enhanced training subsidies through the Enhanced Training Support for SMEs (ETSS) scheme. This means 90% course fee subsidies for all employees regardless of age, higher Absentee Payroll rates, and priority access to SkillsFuture Enterprise Credit. Here is how to maximise your SME training budget.

FEATURED INSIGHTS

AI courses for manufacturing companies. Modules covering quality management documentation, safety compliance, operations optimisation, and supply chain intelligence with AI.

Vietnam's Law on Artificial Intelligence, effective March 2026, is the first standalone binding AI law in Southeast Asia. It introduces risk-based classification, registration requirements, and penalties up to VND 2 billion for non-compliance.

Thailand's PDPA imposes strict data protection requirements on AI systems. With a draft AI law expected in 2026 and new BOT AI guidelines for financial services, companies must prepare for an increasingly regulated environment.

Indonesia's Personal Data Protection Law (UU PDP), fully effective since October 2024, is modeled on GDPR and applies to all AI systems processing personal data. With mandatory AI regulations expected in early 2026, companies must comply now.

Malaysia's PDPA amendments (effective June 2025) introduce mandatory DPO requirements, breach notifications, and data portability. Combined with the new AIGE Guidelines, companies using AI must adapt their data practices.

PERTAMA TOOLS

Beyond advice, we design and build custom AI tools for manufacturing organizations. These are illustrative examples—each engagement produces solutions tailored to your specific needs.

AI-powered defect detection

Solves: Human inspection misses defects under fatigue. AI maintains consistent detection accuracy across all shifts.

Equipment failure forecasting

Solves: Unexpected breakdowns halt production and rush repairs cost more. AI predicts failures before they occur.

Production planning intelligence

Solves: Over-production ties up capital; under-production loses orders. AI improves forecast accuracy with market signals.

Supply chain risk monitoring

Solves: Supply disruptions catch procurement off-guard. AI monitors supplier health and flags risks early.

The highest-ROI applications include predictive maintenance (reducing unplanned downtime by 30-50%), quality inspection automation (catching defects human inspectors miss), supply chain optimisation, and production scheduling. Computer vision and IoT sensor analytics are particularly transformative on the factory floor.

No. We help manufacturers start with targeted AI projects that work with existing infrastructure. A single production line with basic sensor data can be enough to pilot predictive maintenance. We assess your current digitalisation level and recommend the minimum viable data infrastructure needed for each use case.

We specialise in integrating AI with legacy manufacturing environments. This often involves adding IoT sensors to existing equipment, building middleware connectors to legacy MES/ERP systems, and implementing edge computing solutions that work alongside current infrastructure without requiring wholesale replacement.

Predictive maintenance projects often show ROI within 3-6 months through reduced downtime and maintenance costs. Quality inspection automation typically pays back in 6-12 months. Full-scale digital transformation initiatives show compounding returns over 12-24 months as multiple AI systems reinforce each other.

Let's discuss your specific challenges and how AI can drive measurable results for your organization.