TESDA AI Training for Manufacturing in the Philippines

Philippine manufacturers can access TESDA-funded AI training to build Industry 4.0 capabilities. This guide covers relevant TESDA programs for manufacturing AI — from quality inspection with computer vision to predictive maintenance and supply chain optimisation.

- Philippine-registered manufacturing companies

- SEC/DTI registration and business permits

- Manufacturing facility with equipment for OJT component

- Compliance with DOLE safety and labour regulations

- PEZA-registered companies get additional tax benefits

- Assess your manufacturing workforce AI skills gaps

- Register with TESDA as an enterprise training partner

- Submit training plan covering target roles (operators, technicians, engineers)

- Choose training model (DTS, Apprenticeship, or Learnership)

- Deliver training combining classroom and factory-floor practice

- Certify employees through National Competency Assessment

- Measure results against production KPIs

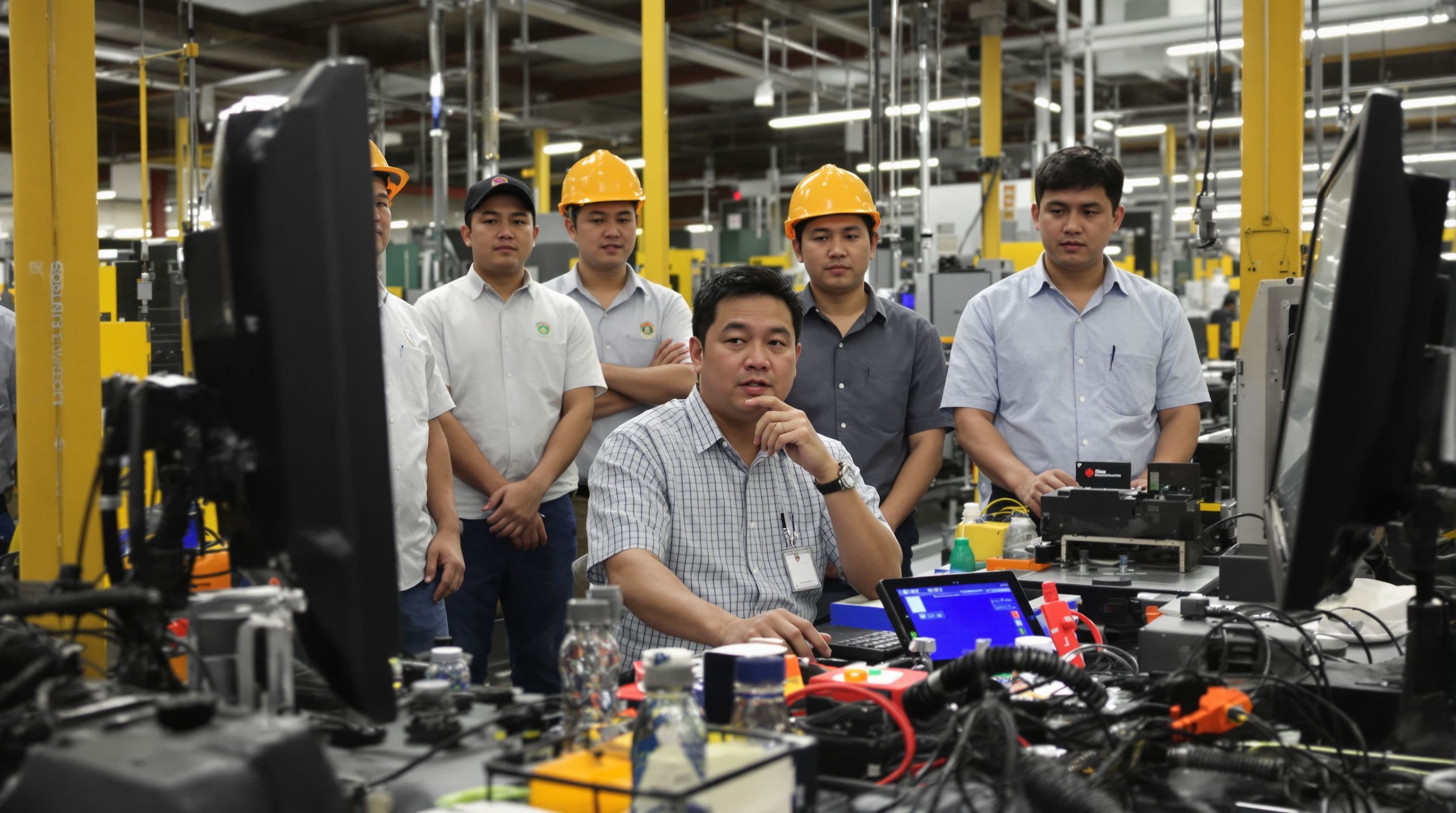

Industry 4.0 in Philippine Manufacturing

The Philippine manufacturing sector is the country's second-largest economic contributor, with key industries including electronics, automotive parts, food processing, and garments. The Department of Trade and Industry's Inclusive Innovation Industrial Strategy (i3S) has identified Industry 4.0 readiness as critical for the sector's global competitiveness.

AI applications driving transformation in Philippine manufacturing:

- Predictive maintenance: ML models that predict equipment failures before they cause downtime

- Quality inspection: Computer vision systems that detect defects faster and more accurately than manual inspection

- Supply chain optimisation: AI-powered demand forecasting and inventory management

- Process optimisation: Machine learning for production scheduling, energy management, and yield improvement

- Safety monitoring: AI-powered camera systems for workplace safety compliance

TESDA Programs for Manufacturing AI

Core TVET Qualifications

- Mechatronics Servicing NC II — Covers automated systems, sensors, and IoT devices that form the foundation of AI-enabled manufacturing.

- Computer Systems Servicing NC II — Essential for maintaining the IT infrastructure that supports AI manufacturing systems.

- Programming NC IV — Develops programming skills for building and maintaining AI applications in manufacturing environments.

- Electronics Products Assembly and Servicing NC II — Critical for the Philippines' large electronics manufacturing sector, including AI chip assembly and testing.

Enterprise-Based Training for Manufacturers

TESDA's Dual Training System is particularly well-suited for manufacturers:

- Theory component: TESDA-accredited institution teaches AI fundamentals, data collection, and basic ML concepts.

- Practical component: Trainees apply AI tools directly to your manufacturing processes — predictive maintenance on your equipment, quality inspection on your product line.

Custom enterprise training topics for manufacturing:

- AI-Powered Quality Control — Computer vision for defect detection, statistical process control with ML, and automated quality reporting.

- Predictive Maintenance with IoT — Sensor data collection, anomaly detection, and maintenance scheduling using AI models.

- Smart Factory Operations — Production planning with AI, energy optimisation, and real-time monitoring dashboards.

- Supply Chain AI — Demand forecasting, inventory optimisation, and supplier risk assessment using ML.

Setting Up a TESDA Training Programme for Your Factory

Step 1: Skills Assessment

Map your workforce against Industry 4.0 competency frameworks. Identify which roles need AI skills and at what level.

Step 2: Choose the Training Model

- DTS (Dual Training System): Best for comprehensive, long-term programmes (6-24 months). Partners your factory with a TESDA institution.

- Apprenticeship: Good for roles requiring deep practical AI skills (3+ months).

- Learnership: Suitable for shorter AI tool training (up to 3 months).

- STEP: Community-based option for training workers from surrounding communities.

Step 3: Partner with TESDA

Register with your regional TESDA office as an enterprise training partner. Submit your training plan and facility details.

Step 4: Deliver and Certify

Run the training programme, then arrange National Competency Assessment for participants.

PEZA and TESDA Combined Benefits

Many Philippine manufacturers operate in PEZA (Philippine Economic Zone Authority) zones. These companies can combine:

- TESDA training subsidies (reduces or eliminates training costs)

- PEZA tax incentives (training expenses are deductible)

- CREATE Act benefits (additional training cost deductions)

This combination can make AI training essentially zero-cost for PEZA-registered manufacturers.

Pertama Partners Manufacturing AI Training

Pertama Partners delivers AI training designed specifically for manufacturing environments in Southeast Asia. We help Philippine manufacturers go beyond TESDA fundamentals to implement production-ready AI systems.

Our Manufacturing AI programs include:

- Computer vision for quality inspection (hands-on with your production line)

- Predictive maintenance implementation (using your equipment data)

- AI for production planning and scheduling

- Industry 4.0 readiness assessment and roadmap

Contact us to build an AI-capable manufacturing workforce.

Frequently Asked Questions

Frequently Asked Questions

Yes. AI applications in food manufacturing include quality inspection (visual detection of contamination or defects), demand forecasting for perishable inventory, process optimisation for cooking/packaging lines, and food safety compliance monitoring. TESDA's enterprise programs can be customised for food manufacturing contexts.

Through TESDA, training costs can be zero to minimal. TESDA scholarship programs fully cover tuition, and enterprise-based training programmes share costs between TESDA and the employer. For SMEs, TESDA's STEP programme can provide community-based training at no cost. Combined with PEZA and CREATE Act incentives, AI training is accessible even for small manufacturers.

Track key manufacturing metrics before and after training: defect rates, unplanned downtime, production efficiency, and inventory accuracy. Philippine manufacturers who have implemented AI after TESDA-aligned training typically see 15-30% improvement in quality metrics and 20-40% reduction in unplanned downtime within 6 months.

- •Mechatronics Servicing NC II

- •Electronics Products Assembly NC II

- •Computer Systems Servicing NC II

- •Programming NC IV (Manufacturing)

- •Custom: AI-Powered Quality Control

- •Custom: Predictive Maintenance with IoT

- •Custom: Smart Factory Operations

Explore AI consulting, training, and solutions in Philippines.

View Philippines hub